How Is Legal Delta 9 THC Made?

The federally compliant delta 9 THC products on today’s market have changed the hemp landscape forever, finding a legal workaround to laws aimed at prohibiting this cannabinoid in adequate dosage amounts. Delta 9, as we know, is the dominant chemical compound found in marijuana, but in hemp, you’ll only get about 0.3% delta 9 in the plant’s chemical composition.

This means that companies need to come up with creative ways to create pure, cost-effective delta 9 isolates that can go into their gummies and other delta 9 formulas. That being said, the process of “making” delta-9 is far more fascinating than you may think.

To Buy Delta 9 THC Products Click Here

-

Product on sale

Delta 9 THC Gummies$30.99

Delta 9 THC Gummies$30.99$54.99

The Initial Conversion: Converting THCa into Total Delta 9 THC

Did you know that “THC” can actually cite to two unique compounds?

- THCa is the precursor molecule.

- Delta 9 THC is the second molecule attaching to the cannabinoid receptors in the body that’s responsible for those psychoactive, intoxicating, and euphoric effects of traditional cannabis.

To be able to convert THCa to delta 9 THC, the flower has to be decarboxylated. Decarboxylation is caused by time and/or heat. When adding heat to the inactive compound of THCa, it then converts to delta 9 at the highest theoretical rate of 87.7%. Hence, why cannabis isn’t eaten raw to get high, but a flame is employed to involve heat, in order to activate the delta-9.

It Starts with Industrial Hemp

All delta 9 products that are sold legally under federal law (2018 Farm Bill) begin with industrial hemp. Extracting delta 9 THC from marijuana would be far easier, because the plant can produce up to 30% of the cannabinoid. But, marijuana remains a federally illegal cannabinoid, and so we rely on the hemp plant, which naturally yields about 0.3% delta 9.

Ideally, the hemp that will be used to make delta 9 products is grown organically and here in the United States, where it’s grown under strict quality standards and without the use of pesticides. When the flowering buds of the plant mature, they’re picked so that the extraction process can begin.

-

Product on sale

Functional THC Gummies$33.99

Functional THC Gummies$33.99$59.99

Creating Delta 9 THC Distillate

Like we said earlier, companies must work with the hemp plant, which only produces about 0.3% delta 9 THC – compare that to the 20% or more CBD that’s abundant in hemp material. To isolate and extract a meaningful amount of delta 9 from hemp can be done, but at a huge cost to the processor, since it takes a lot of time and an enormous amount of raw plant material that gets extremely expensive. Fortunately, there’s a process known as isomerization that’s just as capable of yielding pure, stable delta 9 distillate.

Isomers are compounds that have the same molecular components, but a different molecular configuration. All cannabinoids are isomers, because they all come from the same “mother” cannabinoid, which is cannabigerolic acid (CBGA). CBGA eventually converts into every other hemp cannabinoid as the plant matures.

This is a big deal. Why? Well, because it means that we can take the highly accessible CBD in hemp, rearrange its molecules, and convert into 100% authentic delta 9 THC. This process is known as isomerization, and it’s actually somewhat straightforward.

This is how it’s done:

- Applying a Solvent: First, a solvent is applied to the raw hemp flower buds. This creates an oil-soluble CBD extract.

- Add an Acid: Now, an acid is added to the solvent. A specific acid is selected, because different acids produce different changes to CBD’s chemical structure. There are acids that change the structure of CBD to convert it into pure delta 9 THC.

- Test the End Result: The final step is testing the resulting delta 9 THC distillate to make sure that it is, in fact, delta 9. This is done using liquid chromatography, which makes it easy to analyze cannabinoid extracts.

As you can see, the delta 9 THC in federally compliant delta-9 products is ultimately hemp-derived, and uses the natural, raw plant material to yield a highly stable and cost-effective form of the pure cannabinoid.

Formulating the Delta 9 Product

Now that we have a purified delta 9 THC extract, we can turn it into a product. You’ll notice that right now, you can really only find delta 9 edibles. There is a reason for this – it allows companies to produce delta-9 products that contain no more than the legal limit (0.3%) of the cannabinoid, but in large enough portion sizes that the 0.3% comes out to a meaningful dosage for full effectiveness. Delta 9 gummies are delicious, so nobody will mind eating an extra-large gummy to get in some THC action.

Producing a delta 9 gummy can look different from company to company. But generally, you need to source high-quality ingredients, and aim to produce a product that’s as free of additives as possible. In an ideal world, the gummy is naturally flavored and sweetened, and is free of chemical preservatives.

To produce a delta 9 THC gummy, a company usually uses gelatin or pectin, which creates that classic gummy texture. Pectin is fruit-derived, and gelatin is animal-derived, so if you are a vegan, pay attention to which of the two ingredients is used in a particular gummy product.

-

Product on sale

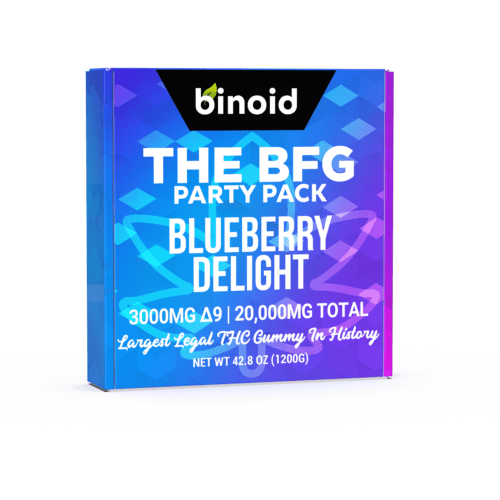

The BFG – 3000mg Delta 9 THC Gummy$128.99

The BFG – 3000mg Delta 9 THC Gummy$128.99$239.99

Lab-Testing Through a Third-Party Source

At this point, the delta 9 THC must undergo a third-party lab-testing process, which is required by law. The company must send the product to a state-authorized testing facility, where it’s analyzed for its purity, safety, potency and breakdown of chemical compounds. These lab reports are then returned to the company, and, of course, should be made available to the public.

Packaging

The final step is packaging. Here is where companies must make sure that their delta 9 THC product is sealed airtight so that it stays fresh – otherwise, the compounds can lose their potency and flavor. The packaging must include serving size, serving instructions and a list of ingredients, as well as other pertinent information such as milligram strength.

Delta 9 THC: A Cannabinoid with Humble Origins

Delta 9 THC may be abundant in the marijuana plant, but to extract it from marijuana would be prohibited under federal law. Fortunately, we have isomerization, a process that’s both cost-effective and safe. This means that the delta 9 products you’re consuming from Binoid are all made using the above steps, which is how we are able to keep our prices so low while still delivering nothing but top-notch quality.

To Buy Delta 9 THC Products Click Here

-

Product on sale

Delta 9 THC Gummies – Bundle$83.99

Delta 9 THC Gummies – Bundle$83.99$154.97